The RHODaS project is at the forefront of reshaping power converter technology for heavy-duty electric transport. In a new report by BOSMAL titled “Experimental Results and Validation of Lab-Scale Power Converter Prototypes”, a comprehensive analysis of experimental findings and validation processes for these pioneering converters are provided.

This report marks a critical step forward in the project, showcasing research outcomes, experimental data, and validation strategies. The report focuses on the development of low-power converters (LPC) and their relevance to the testing of high-power converters (HPC).

The testing of Low-Power Converters (LPCs) plays a crucial role in developing High-Power Converters (HPCs) within the RHODaS project, as insights from LPC testing directly inform and enhance HPC design and validation.

LPCs are used to validate key concepts, such as modulation techniques (CB-PWM and M-SPWM) and protection algorithms, ensuring optimised efficiency, reduced harmonic distortion (THD), and lower common-mode voltage (CMV). Experimental setups simulate real-world conditions, and the results guide HPC testing methodologies.

The analysis of standards and development of LPC test plans provide a foundation for rigorous HPC testing, covering electrical, environmental, mechanical, and safety aspects. Additionally, the scalability of LPC designs to HPCs addresses challenges at higher power levels, paving the way for their application in heavy-duty electric transport.

In essence, LPC testing validates concepts, optimises performance, and refines safety protocols, ensuring HPCs meet the demands of efficient, reliable, and safe transport solutions.

Addressing the Gaps in Standards

The report reveals that current standards fall short in addressing the novel requirements of the next generation of electric vehicle converters. To bridge this gap, the RHODaS team conducted a thorough analysis of existing standards and proposed a comprehensive test plan for HPCs. This plan includes electrical, environmental, mechanical, and safety tests, designed to ensure efficient and reliable operation over the converters’ lifetime.

Experimental Testing and Results

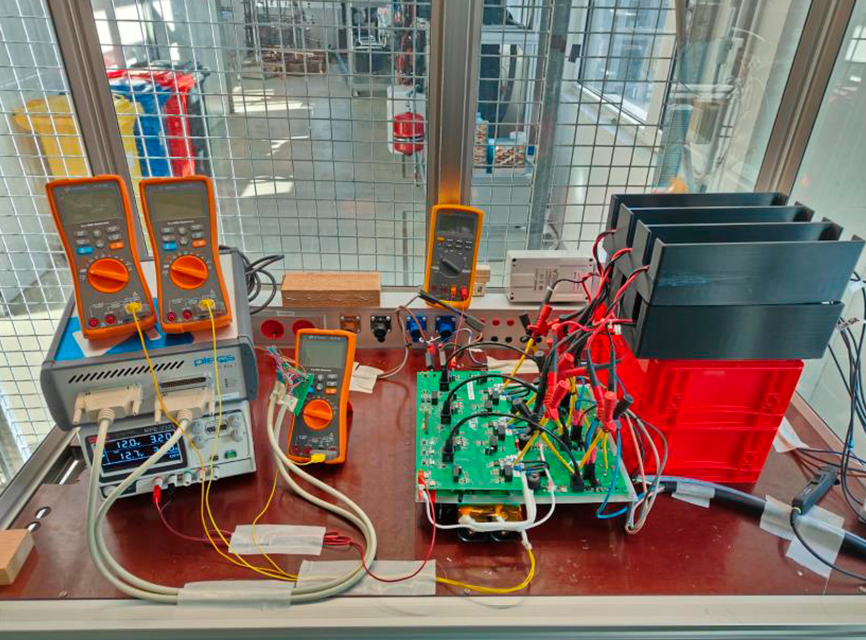

The experimental phase focused on evaluating LPC prototypes under various conditions:

- Electrical Parameters – Basic and advanced electrical tests to assess performance.

- Environmental and Durability Tests – Ensuring resilience under operational stresses.

- Safety Measures – Verification of protection mechanisms and fault tolerance.

Key testing involved two prototypes:

- The UPC converter, tested for electromagnetic interference (EMI), harmonic distortion (THD), and efficiency.

- The AIT converter, tested for high-voltage efficiency and system performance.

Both prototypes were assessed at 800 V DC, yielding critical insights into the performance of hybrid silicon carbide (SiC) and gallium nitride (GaN) topologies in power converter systems.

Efficiency and Performance Advancements

One of the standout findings was the performance of the Carrier-Based Pulse Width Modulation (CB-PWM) method. Compared to the Modified Sinusoidal PWM (M-SPWM), CB-PWM demonstrated:

- Higher Efficiency: Superior performance across all switching frequencies, especially at higher rates.

- Lower THD Values: Enhanced power quality, even at elevated frequencies.

- Reduced Electromagnetic Interference (EMI): Lower common-mode voltage (CMV), crucial for protecting motor health in electric drives.

These results underscore CB-PWM as the optimal modulation strategy for heavy-duty applications.

Validation of Protection Mechanisms

The T-Type converter’s protection algorithms were also validated during testing. These algorithms ensure seamless transitions between operational modes during fault conditions, safeguarding the converter’s integrity. The system quickly returned to normal functionality without compromising performance, highlighting its robustness under challenging conditions.

Driving the Future of Heavy-Duty Electric Transport

The findings from the testing confirm the effectiveness of the hybrid SiC-GaN T-type topology in improving power converter efficiency. These advancements will be applied to the HPC, which will undergo rigorous testing in alignment with updated standards to validate its long-term benefits.

The RHODaS project continues to push the boundaries of power conversion technology, paving the way for more efficient, reliable, and sustainable heavy-duty electric transport solutions.

You can view and download the full report here.