As electric vehicles (EVs) continue to evolve, ensuring efficient thermal management for high-power converters is critical to maintaining performance, reliability, and longevity. RHODAS is spearheading advancements in this field through the development and validation of an innovative Thermal Management System (TMS) designed for a 150 kW High-Power Converter (HPC).

Recent laboratory tests have rigorously evaluated the TMS, focusing on its ability to regulate operating temperatures, prevent overheating, and enhance energy efficiency. The findings mark a significant step forward in the pursuit of lightweight, high-performance cooling solutions for heavy-duty electric transport.

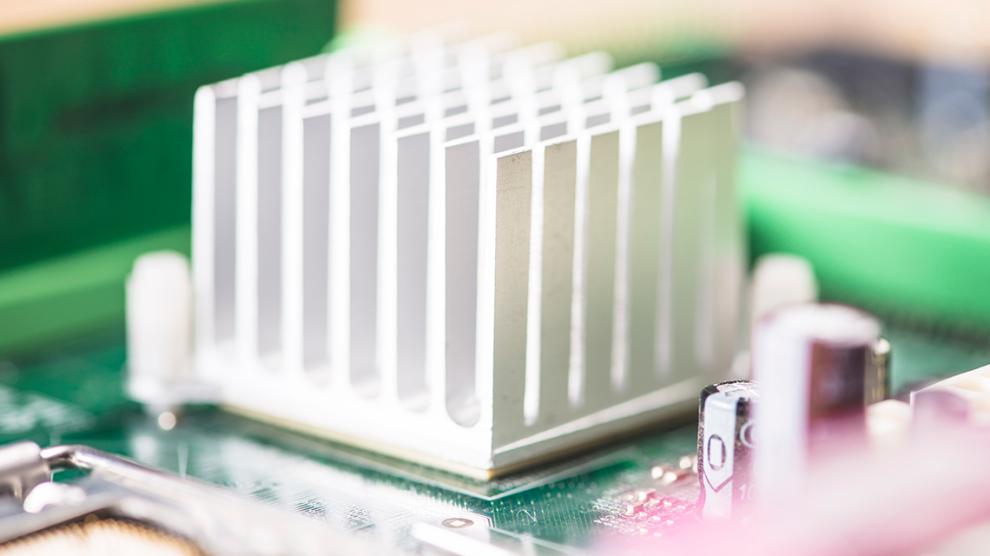

Innovative Heatsink Design: Copper vs Aluminium

The research explored two primary heatsink prototypes—one made from copper and the other from aluminium—to compare their effectiveness in heat dissipation. Notably, the aluminium heatsink demonstrated a significant weight reduction while maintaining comparable thermal performance, making it a highly attractive solution for EV applications.

By reducing component weight, aluminium heatsinks contribute to overall vehicle efficiency, helping to extend battery range and lower energy consumption. Further tests confirmed that aluminium heatsinks remained watertight and gas-tight under high-pressure conditions, reinforcing their suitability for real-world deployment.

Comprehensive Testing for Maximum Reliability

The testing programme was structured into two key phases:

Component-Level Testing: Each individual TMS component (heatsink module, radiator, fan system, and coolant pump) was subjected to controlled test conditions to evaluate thermal and hydraulic performance.

System-Level Validation: The fully integrated TMS was tested to assess its overall effectiveness in dissipating heat under various operating conditions.

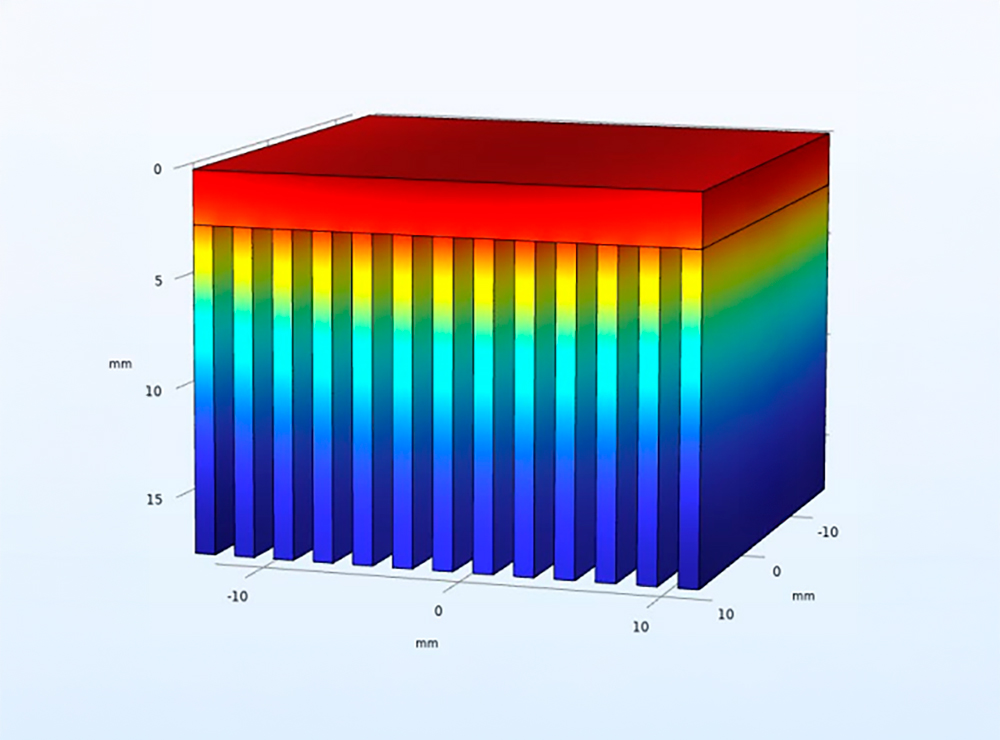

By leveraging Computer-Aided Engineering (CAE) and Computational Fluid Dynamics (CFD) simulations, researchers optimised the heatsink’s geometry, material properties, and cooling performance, ensuring its scalability for future applications.

Impact on Sustainable Electric Transport

The successful validation of the RHODAS Thermal Management System paves the way for more reliable and efficient power converters in EVs. By improving thermal regulation, this innovation directly contributes to:

- Enhanced power converter lifespan

- Greater energy efficiency in EV powertrains

- Reduced overheating risks and improved safety

- Lower greenhouse gas emissions through optimised performance

As the electric mobility sector expands, effective thermal management solutions will play a vital role in accelerating the transition to zero-emission transport. The RHODAS project is at the forefront of this effort, shaping the future of high-power converter technology.

For further details on the lab testing and validation of the RHODAS Thermal Management System, explore the full report here >